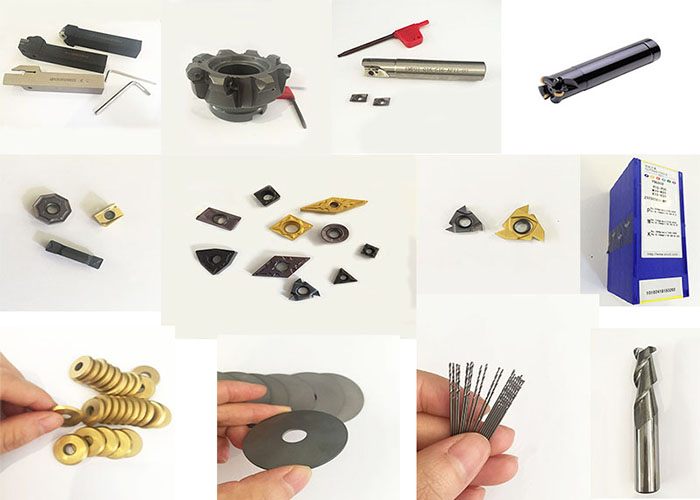

Fault Analysis of Common Carbide Tool Wear Problem

Views : 420

Update time : 2016-11-11 10:54:13

1.Materials of carbide cutting tool

The determine factor impact cutting tool performance is cutting tool material,this with a great influence for cutting tool processing efficiency, processing quality, processing costs and tool life.

The harder the tool material, the better its wear resistance, the higher the hardness, the lower the impact toughness, the more brittle the materials. Hardness and strength is a contradiction, but also the key point that tool materials should overcome.For graphite cutting tools,normal tialn coating should select tool material with an appropriate better strength, that is slightly higher with cobalt content;For diamond-coated graphite cutting tools, should choose cutting tool material with better hardness, that is slightly lower cobalt content.

2.Geometrical angle of carbide cutting tool

Graphite tool to select the appropriate geometric angle, help to reduce the vibration of tool, in turn, the graphite workpiece is not easy to collapse.

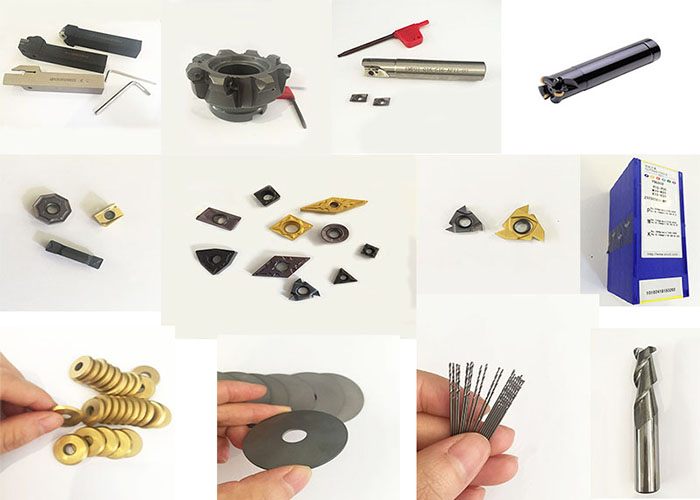

The determine factor impact cutting tool performance is cutting tool material,this with a great influence for cutting tool processing efficiency, processing quality, processing costs and tool life.

The harder the tool material, the better its wear resistance, the higher the hardness, the lower the impact toughness, the more brittle the materials. Hardness and strength is a contradiction, but also the key point that tool materials should overcome.For graphite cutting tools,normal tialn coating should select tool material with an appropriate better strength, that is slightly higher with cobalt content;For diamond-coated graphite cutting tools, should choose cutting tool material with better hardness, that is slightly lower cobalt content.

2.Geometrical angle of carbide cutting tool

Graphite tool to select the appropriate geometric angle, help to reduce the vibration of tool, in turn, the graphite workpiece is not easy to collapse.